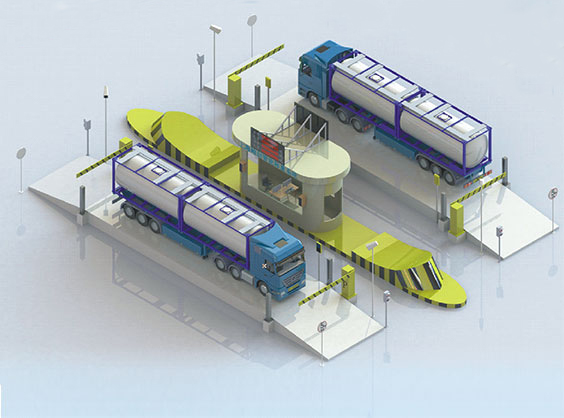

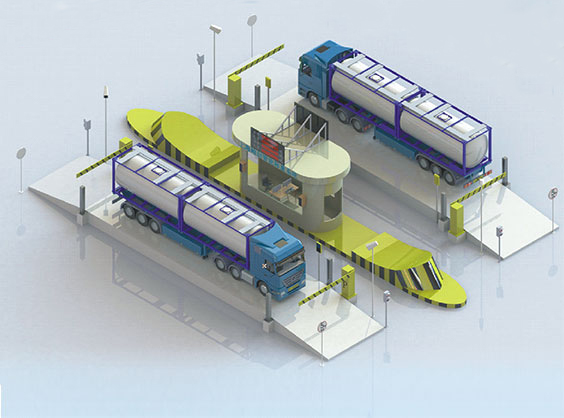

Product introduction:

The unattended intelligent weighing system is Electronic weighbridge manufacturer The intelligent weighing control system integrates automatic weighing of the weighbridge, online weighing of multiple weighbridges, anti cheating weighing of the weighbridge, and remote monitoring of the remote weighing. The unattended intelligent weighing system can quickly, accurately, stably and reliably complete the whole weighing process without manual intervention when weighing cars, Management personnel can remotely monitor, query, print and other operations for measurement process and measurement data.

Product features:

In the whole process of unattended truck scale, the metering data can be automatically and reliably collected, automatically judged, automatically commanded, automatically processed and automatically controlled to minimize the drawbacks and work intensity caused by manual operation, and improve the informatization and automation of the system. The management department can understand the current production and logistics status through the summary report in the system; For the financial settlement department, clear and accurate settlement statements can be obtained; The warehouse management department can learn about its own receipt and delivery of goods. The data of electronic weighbridge manufacturers can be consulted at any time, so it also strengthens the consistency of management, shortens the response time of decision-makers to production, improves management efficiency, reduces operating costs, and promotes enterprise information management.

Product configuration:

● Weighbridge: static weighing weighbridge;

● License plate identifier: automatically identify license plate number;

● Road gate: one vehicle and one pole;

● Traffic light: remind the passing status of weighed vehicles;

● Network monitoring camera gun: realize monitoring and capturing in the head, tail and carriage;

● Infrared grating: vehicle positioning to prevent cheating;

● Electronic control cabinet: automatic control weak current part;

● Voice equipment: computer voice prompt or weighing room call;

● Control computer: storage of weighing data and control of external equipment;

● Hard disk video recorder: real-time recording of monitoring data;

● Electronic weighing instrument: digital weighing instrument to meet the static weighing requirements of truck scale;

● Printer: print reports and weighing documents;

● Large screen: display current weight information;

Product function:

● Vehicle number recognition function: the camera gun for vehicle number recognition at the entrance and exit of the truck scale can automatically identify the vehicle number through the capture camera without manual input, which improves the working efficiency. After the vehicle is weighed, wait for the scale platform to stabilize, the system will automatically read the instrument data to weigh, and the system will automatically save the weighing data and the captured photos into the database.

● Video monitoring anti cheating: the system is equipped with two camera guns, which are synchronized with the system software. The system software can observe the weighing situation of vehicles within the monitoring range of the camera gun in real time. When the vehicle is stable on the weighing platform, the system automatically weighs, instantaneously captures two groups of pictures and weighing records of the front and rear license plates, and saves the weight data, license plate number The time, etc. are superimposed on the record image, so that the same amount of record query can be called in the future, and the gross weight image and tare weight at the time of weighing can also be accessed. It is convenient for management personnel to review and supervise heavy vehicles. It also prevents the driver from taking advantage of the difference in the tare weight of the vehicle to cheat when the cart is too rough and the cart is skinned.

● Infrared anti cheating: the system installs a set of infrared vehicle separators at both ends of the truck scale. When the weighing vehicle is mounted on the truck scale, the grating detects that the weighing vehicle grating will send a signal to the system through the aperture cable. The system first controls the signal light, so that the signal light changes from the original green light to the red light, reminding other waiting vehicles that cannot be mounted on the scale, Electronic weighbridge manufacturing process When the weighing vehicle is not fully loaded, the grating continuously sends the signal of unfinished detection to the system, and the system does not allow weighing, and prompts the driver through voice.

● The intelligent automatic barrier module realizes the standardized management of truck scale weighing and the control of non weighing vehicles entering and leaving. The electronic weighbridge installation equipment includes: automatic barrier, car barrier, anti smashing coil, axle detector, intelligent control switching unit and intelligent controller; The intelligent car stop system has the function of preventing cars from crashing. When the vehicle does not leave the railing, the system automatically detects that there is a vehicle under the railing through the ground sensor coil and the vehicle detector. The electronic weighbridge feature system will automatically send the railing opening signal to keep the railing open until the vehicle leaves, and the railing will fall automatically.

● Voice broadcast and active function power amplifier speakers, the system will play different voice prompts in different weighing processes by controlling the voice system, such as "Please drive the car to the middle and get off, thank you!" "Weigh successfully, please weigh down, thank you" After the weighing is completed, the gross weight and net weight of this weighing will be read out by voice; The weighing clerk can direct the driver to move the vehicle through the microphone.