The weighbridge often encounters error problems in daily application, which not only affects the reliability of weighbridge use, but also harms the interests of weighbridge users to varying degrees. It is an important problem to study the error source of the weighbridge. Analyzing the weighing performance of the weighbridge and grasping its error source will help to improve the quality and efficiency of the weighbridge verification work. The following is a brief introduction to the four causes of the weighbridge sensor error:

1. Four corner eccentric load error

The change of the position of the weight on the scale platform shall not cause the change of the weighing measurement result, so the bias error of the four corners comes from the sensitivity of the weighing sensor. In order to reduce the bias load error of four corners, the weighbridge is connected with a potentiometer in each sensor branch. The signal output of each branch can be balanced by adjusting the resistance value and making use of the different voltage division of different resistors.

2. Repeatability error

The repeatability error is the difference between the output readings of the load cell obtained from several consecutive process tests under the same load and the same environmental conditions. It mainly includes the lateral force of the weighbridge sensor and the repeatability error caused when the sensor conditions are not met. Due to the limitation of the site environment, it is easy to cause the load receiver to move up and down, resulting in the non vertical force of the weighing platform on the load sensor. The lateral force on the sensor is caused by the design and manufacturing error of the force transmission mechanism of the scale body, which is specifically reflected in the repeatability error generated by the levelness of the upper and lower mounting base planes of each sensor and between them, the overall stiffness of the scale body and the relevant local stiffness. When weighing the electronic scale, the force transmission characteristics of the mechanical force transmission mechanism of the scale body, the consistency of sensor parameters, and the excitation voltage of the sensor must meet certain conditions. The force transmission mechanism of the scale body should ensure that the load borne by the sensor is proportional to the measured weight, so as to ensure the accuracy of the weighing measurement results.

3. Weighing error

The linear change and zero drift of sensor weighing are the direct causes of weighing error. Due to the influence of temperature difference, floating dust and other external forces, the relationship between the load borne by the sensor and its corresponding output voltage is not linear, which makes the weighing linearity of the electronic scale sensor change greatly. The weighbridge is affected by different sizes and repeated reciprocating impact loads in the use process. The stress of the sensor is very complex, resulting in changes in the contact of the sensor, changes in the original state of the timing, resulting in zero drift and errors.

4. Discriminatory error

Discriminant force reflects the ability of the weighbridge to respond to small changes in load. The purpose of the discriminant force test is to check the connection and friction of the weighbridge structure, because the friction stress in the mechanical connection is the main source of the discriminant force error. In addition, because discrimination is aimed at small changes, the resolution of the load cell and the weighing instrument also has a greater impact on the discrimination error.

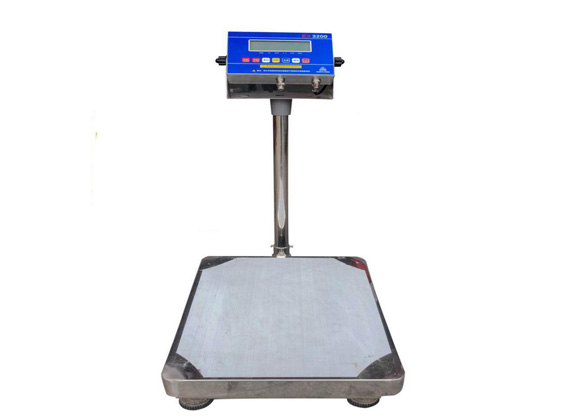

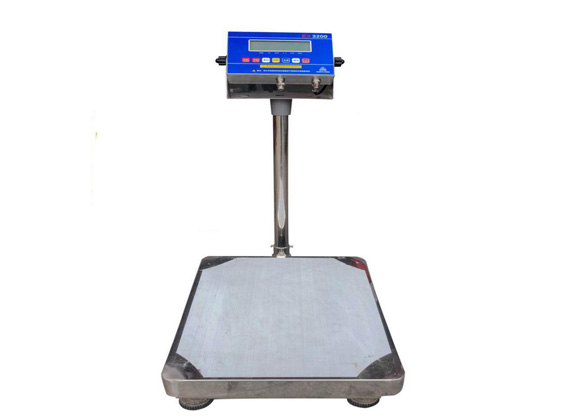

Jiangmen Lidong Electronic Weighing Instrument Co., Ltd. is a Jiangmen electronic weighing instrument manufacturer that specializes in the development and production of weighbridge, electronic weighing instrument, electronic truck scale, electronic ground scale, axle weight scale, industrial automatic packaging equipment, automatic batching equipment and other large-scale industrial weighing equipment. Looking forward to your cooperation!

(Some materials of this website come from the network. If the information displayed on this website infringes your copyright or other legitimate rights and interests, please notify us in time, and this website will be deleted in time.)