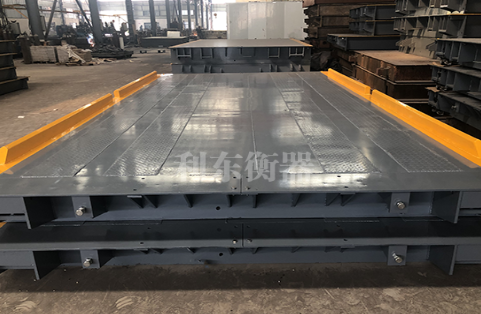

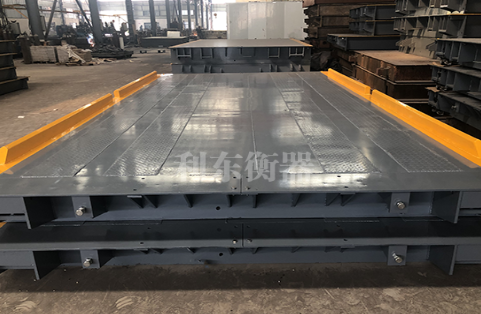

The electronic truck scale is generally divided into several parts. The truck scale used for weighing shall have a load surface (the load surface shall be of good quality, not easy to deform, and impact resistant). The electronic truck scale also needs a sensor and an electronic converter to receive, analyze, identify and transmit the measured weight data. This intermediate process is called transmission power conversion system; There must also be a digital indication system; It is a monitor. These three parts are the structure of truck scale.

Electronic truck scale and weighbridge are industrial scales for truck weighing. The common use of truck scale is to determine the weight of bulk cargo according to the whole vehicle. In this case, the information provided by truck scale has become an important part of the transaction. Law enforcement agencies also often use truck scales to check whether vehicles running on the road are overweight. It is also used to monitor the import and export of solid waste treatment and recycling centers, construction sites and other facilities.

The function of electronic truck scale is to weigh the goods carried by the vehicle. Generally speaking, electronic truck scale is widely used in construction sites, logistics companies, large farms, grain purchase centers, building materials factories and other places. In other words, after weighing the total weight of the vehicle, weigh the vehicle and subtract the weight of two vehicles from the total weight, that is, the weight of the transported goods. In fact, in many cases, electronic truck scale and electronic weighbridge are used together. They perform their duties and provide weighing services for the company's factories and commercial organizations.

(Some materials on this website come from the Internet. If the information displayed on this website infringes the intellectual property rights or other legitimate rights and interests of the media or individuals, please notify us in time, and we will delete it immediately.)