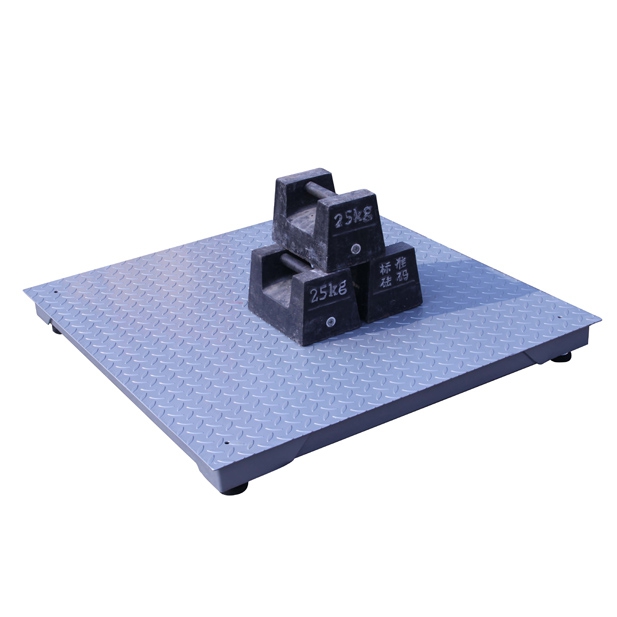

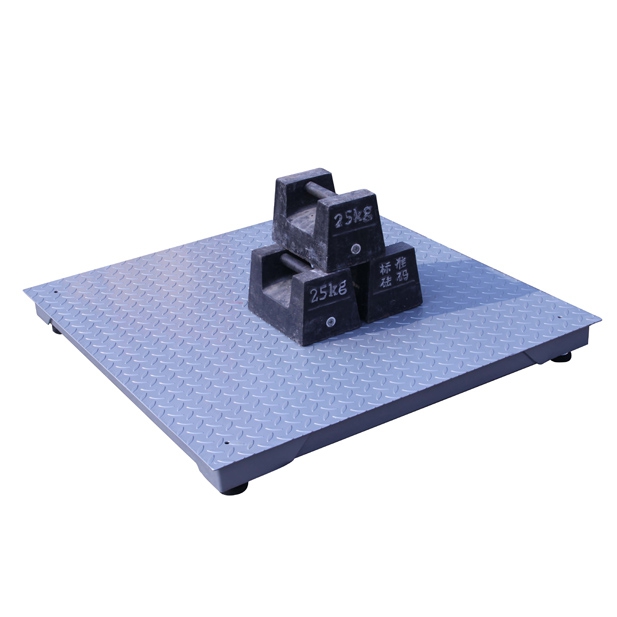

The electronic weighing instrument is a fine measuring instrument, which usually involves the connection of sensors, microprocessors, wireless transceiver, display, printing and other skills. Only by accurately using the electronic weighing instrument and making its output data accurate and reliable can it play a positive role in the company's management and development. Therefore, when using, it is necessary to have a full understanding of commodities. Here are some simple points of view on the accurate use of electronic weighing apparatus.

1. Carefully read the commodity operation instructions and relevant materials provided by the manufacturer, and understand the commodities before use. If necessary, go to the manufacturer for training, and operate with certificates.

2. Contact the nature of the company's work and work out the corresponding handling system. The characteristics of the weighbridge are operated, handled and protected by specially assigned personnel. Non metrological personnel are prohibited to operate and use the weighbridge. If conditions permit, it is recommended that the power supply of the weighing system be turned off in places where electronic weighing scales are specially stored.

3. Regularly verify the accuracy of the electronic scale, especially the electronic scale used for trade settlement before the first use, and make corresponding periodic verification records and current operation records, and timely eliminate any problems found.

4. When the electronic weighing instrument breaks down, the weighbridge shall be repaired in time, and the repair record shall be made to record the fault condition in detail, the equipment, title and weighbridge type replaced during the repair for reference in future repair. In particular, changes in some parameters, such as the internal code value of calibration parameters, wireless communication frequency, etc., are usually filled in by the manufacturer for repair, and a copy is left for the user.

5. Keep the whole electronic scale clean. Especially for the appearance and micro printer, it can be cleaned with neutral cleaning agent such as anhydrous alcohol. In the wet environment with large dust, it can be cleaned in time to reduce unnecessary wear and extend the service life.

6. The appearance of the electronic weighing instrument shall be charged in time, and the battery shall not be over discharged. It must be charged in time after work every day to ensure normal work the next day.

7. Pay attention to:

(1) Measure within the useful range of the electronic scale. Generally, the electronic scale has the minimum and maximum weighing rules. Do not measure beyond the rules.

(2) The reading and printing of measurement data must be carried out after the appearance is securely marked to avoid unnecessary errors.

(3) Before measuring goods, the weight of ropes and hoppers (cans) used for weighing shall be peeled from the price of the weighbridge to ensure that the weighing result is gross weight.

⑷ In the measurement process, the zero return condition shall be investigated for a period of time to avoid the zero drift affecting the measurement results of the weighing instrument.

8. The electronic weighing instrument that does not need to be used for a long time should be stored in a dry place, and the battery should be charged regularly (usually within three months) to avoid self discharge, damage and scrap of the battery.