Product introduction:

The electronic forklift scale can be used to automatically weigh materials while loading materials, and is widely used in the control of cargo loading in logistics, warehousing, workshops, coal mines, ports, buildings and railway transportation.

Functions of electronic weighbridge:

● Electronic scale for simultaneous handling and weighing, suitable for pallet weighing and often moving weighing occasions

● Weighing platform is composed of hydraulic manual handling mechanism and load cell, stainless steel junction box, weighing display instrument and signal cable

● Hydraulic driving platform lifting, manual vehicle operation

● Alloy steel sensor: strong lateral force resistance, overload capacity, stable performance, high accuracy, and good reliability

● Special weighing instrument: zero setting, tare removal, accumulation and other functions; Unit switchable (kg/ib)

● Rechargeable battery power supply, AC/DC dual purpose, power failure can also be used continuously for 80 hours

● The basic surface of the scale is sprayed with plastic, which has the characteristics of anti-corrosion, rust prevention, and professional design. The scale body is more solid, which can get rid of the loss force caused by weighing and moving at the same time, and increase the service life of the scale.

● Leak proof oil cylinder: to avoid oil leakage, the durability of the oil cylinder will not be affected if the operator is rough in hydraulic operation

● High strength nylon wheels are used for the moving rollers of the carrier, which makes it easier to push.

Operating environment of electronic forklift scale:

● The forklift electronic scale shall be preheated when in use, and the boom shall be lifted 5-10 times. The oil pressure and sensor shall be preheated to the normal operating temperature

● During operation, when the tipper is lifted, the electronic weighbridge design should first control the control lever of the boom to the rear position, that is, the tipper is at the rear end

● The boom system shall be strictly lubricated to reduce the friction coefficient of the boom

● Select a flat ground for weighing

● The process of lifting the boom should control the speed evenly

● It is better to set to zero when the vehicle stops running

● Avoid vehicle driving during weighing. If it is necessary to drive, the vehicle speed should be controlled at about 10km/h

● If the electronic weighbridge is equipped with multiple tippers, the used tippers must be calibrated during weighing

● Start the vehicle before starting the scale, and turn off the vehicle power after the scale is turned off

● Avoid water flowing into the instrument during cleaning to avoid damage

Electronic scale composition:

● The car body is the whole frame of the electronic forklift scale,

● Four pressure weighing sensors are used to measure the pressure changes borne by the on-board hydraulic system

● Five hole junction box, which is used to collect the pressure signals borne by four sensors and transmit the signals to the on-board instrument

● On board instrument, calculate the weight data and display the weighing results on the screen of the instrument

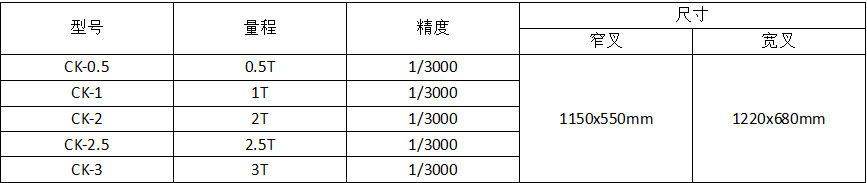

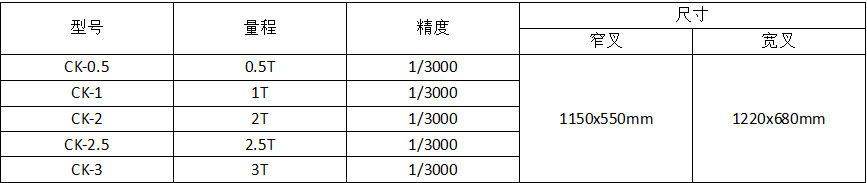

Weighing range and specification:

Optional configuration:

Instrument: with printing instrument, stainless steel instrument, upper, lower and limit alarm function instrument, RS232 interface connected to computer instrument, counting and weighing instrument, etc.

matters needing attention:

● The product shall not be overloaded, and shall be specially used for weighing. Pay attention to the humidity and dust in the operating environment

● During operation, there shall be no rapid drop under heavy load to avoid damaging the hydraulic cylinder and weighing main parts

● The hydraulic device cannot be raised when the forklift scale is pushed under heavy load

● At the first use, Electronic weighbridge manufacturer First use up the pre stored power before charging. The first charge will take more than 12 hours

● There will be an undervoltage prompt before the weighing display is powered off. At this time, the battery should be charged immediately to ensure the service life of the battery. The first three times must be charged within 10-12 hours to ensure that the battery is fully activated. It can be charged for 4-6 hours each time. Damage to the battery will affect the normal use of the forklift and the stability of the weighing display

● Forklift scales shall be protected from exposure, water, moisture, etc

● 220v AC power supply is used for instrument charging

● The front and rear casters are made of polyurethane as standard, and should not be used on high temperature ground to avoid damage.